Aggression or Affection: Stiffness as Medium for Social Expression

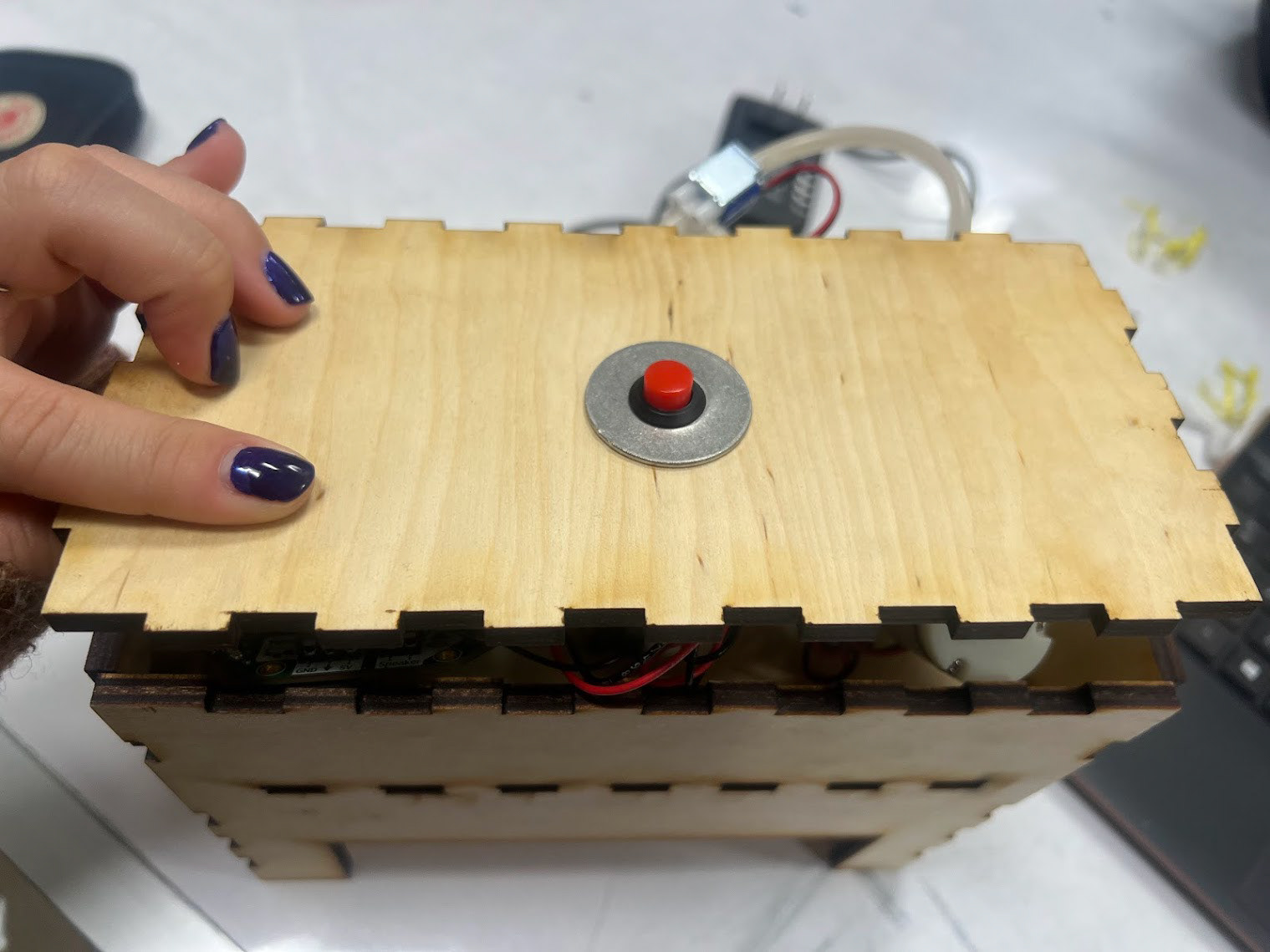

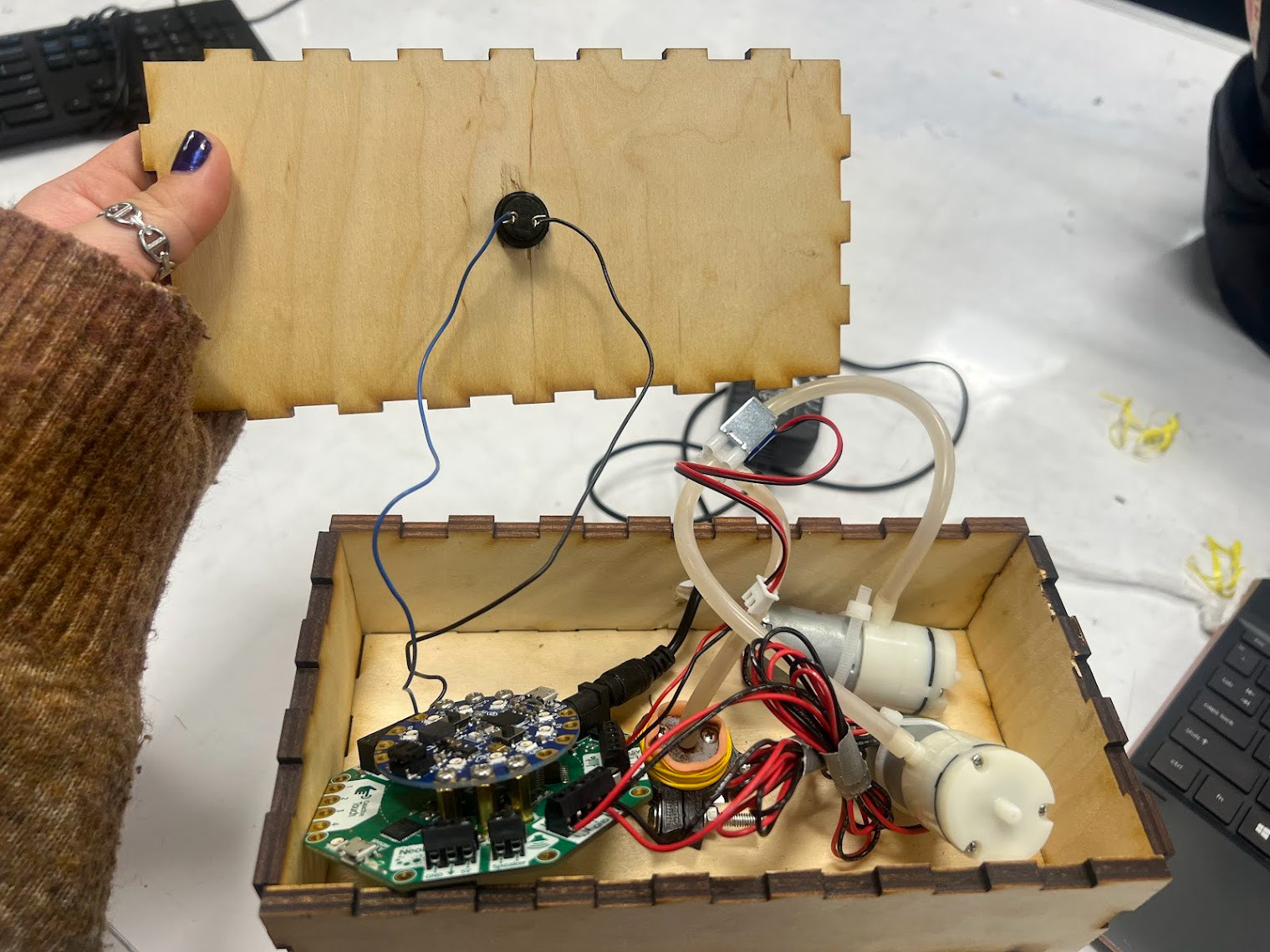

Aggression or Affection is an interactive silicone finger that mimics the feeling of scratching and rubbing, exploring how gestures with the same translational motion can feel dramatically different through changes in stiffness and hardness. The emulation of different social touch gestures of aggression and affection is enabled by the use of a hybrid granular and fiber jamming mechanism combined with pneumatic actuators.

Creative Design Opportunities

The project demonstrates the unique expressive potential for soft technologies, specifically variable stiffness mechanisms, for social and emotional communication. By adjusting the compliance (stiffness) and hardness of the finger, I was able to shift between gestures that are perceived as affectionate and aggressive. This highlights an underexplored design space in human robot interaction: how material properties like stiffness can convey complex social cues.

The hybrid fiber and granular jamming enable the finger to exhibit changes in both overall stiffness and local hardness. Although the emulation of scratching was not fully realized, the success in differentiating between compliant and stiff states suggest new methods for designing a haptic experience.

Many viewers of the piece were uncomfortable with the mechanism but were still willing to interact with it, highlighting the complexity of emotional responses to the ambiguous, soft robotic touch. This suggests that soft systems can provoke both curiosity and caution, an emotional tension that can be intentionally designed for future interactive pieces. One viewer even suggested placing a different base for the hand as the surface in which they placed their hand affected their sensory experience. Future designs could incorporate a variety of base textures or materials to further modulate the emotional tone of the interaction.

Successes

Changes in Stiffness and Hardness

When the vacuum is on, there is a noticeable difference in compliance through the fiber jamming. More force is required to move the finger when the fibers are jammed than when they are in their relaxed state. Additionally, the finger feels harder and is less squishy through the granular jamming. Unfortunately, these changes in compliance and hardness are not enough to emulate the feeling of scratching. This is due to the silicone used as the casing for the grains and fibers.

Creating the Finger

The feeling of a fingertip was successfully emulated through the use of the inner mold and by leveraging the layers created when 3D printing. By applying the Rebound-25 on the inner mold and allowing for gravity to create an even layer, I was able to create a smooth inside. I applied 4 layers in total and flipped the finger 3 times (2 layers placed right side up, 2 layers upside down hanging on the bowl) to create an even surface. The thick layer allowed me to flip the silicone inside out.

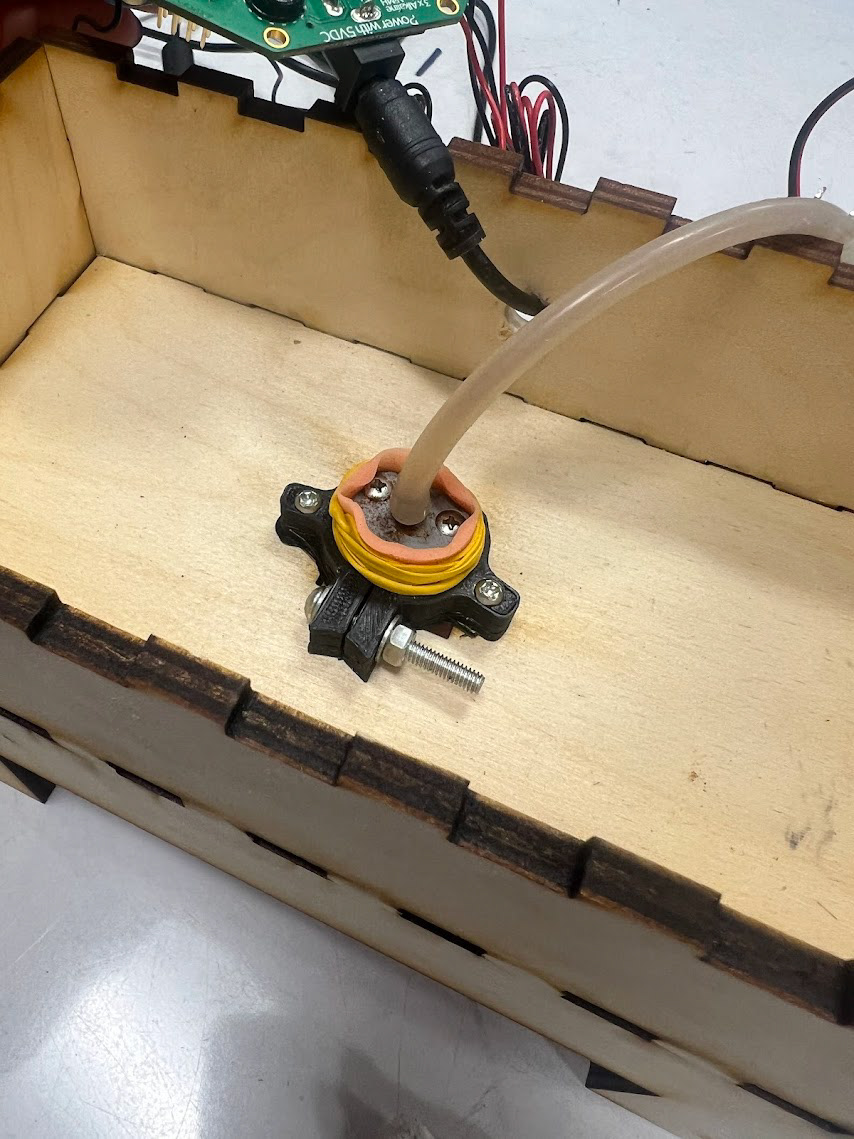

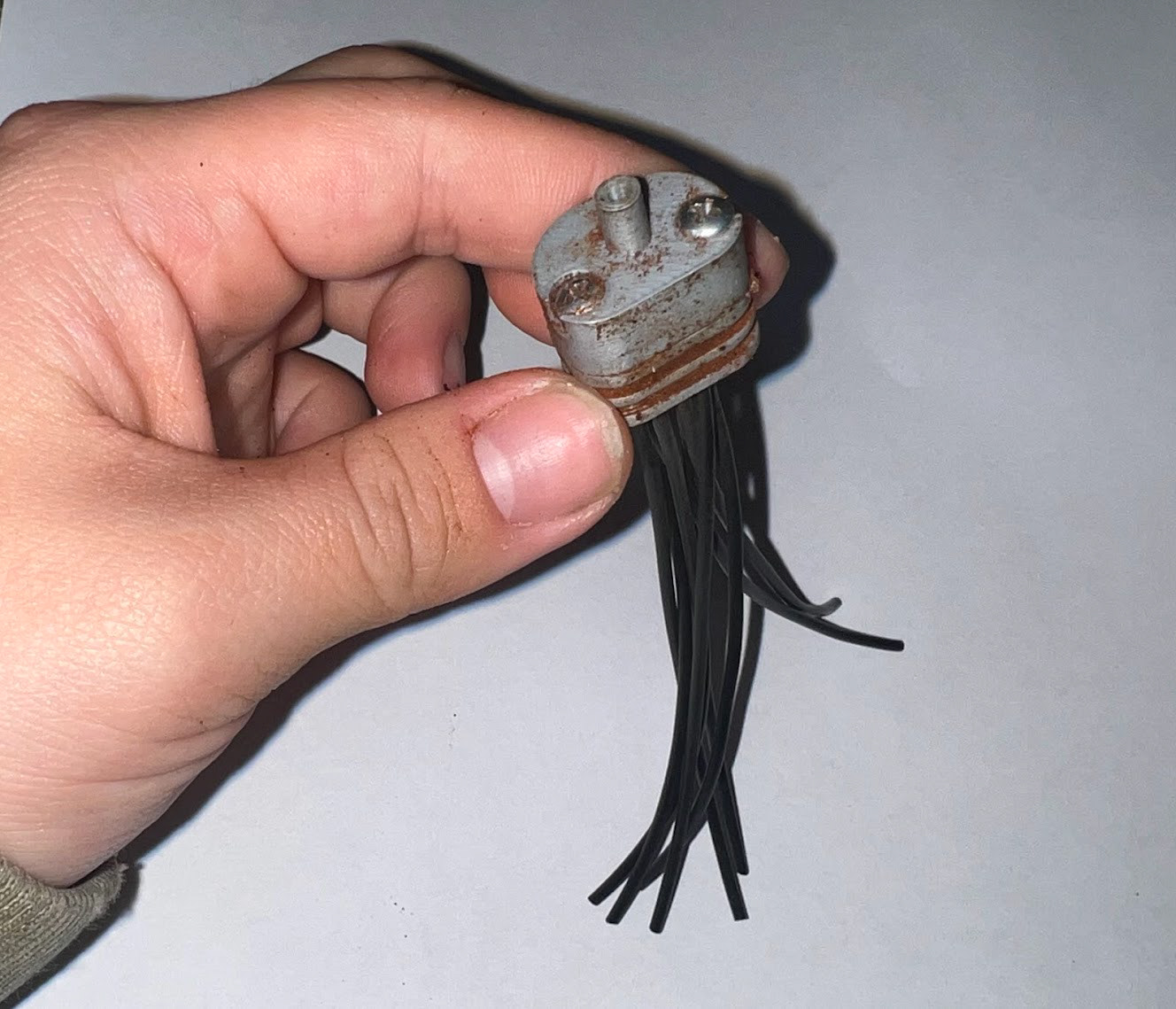

Custom Pipe Fittings

The custom fittings were a success because the fibers were successfully held in place and air can easily flow in and out of the spout of the finger. This was enabled through the use of 3D printing as small holes and crevices could be created and modified quickly.

Failures

Hardness Mechanism

The basis of aggression is the emulation of scratching of a fingernail. While the finger achieves a greater hardness with the vacuum, the feeling of the fingernail was not. This can be due to the silicone envelope of the finger. Since the silicone was too thick, the feeling that the granular jammed glove wasn’t able to be achieved. In addition, it was harder to fit the grains and fibers into the silicone and the coffee grounds were further broken down. A possible fix can be using a thinner envelope or adding a solid fingernail to one end of the finger. Since fiber jamming required a significant force to induce a change in orientation (demonstrated by Mark’s arm project), an external actuator must be used. The change in compliance through jamming would still meet the soft robotic requirement.

Air Tightness

While preliminary tests showed that air tightness could be achieved with the custom pipe ring, the final iteration had air leaking on the ends. I used a rubber band at the top to make a tighter fit around the inner parts, and this held well for the demo. For future iterations, I would test more with different pipe ring sizes to prevent being slowed down by 3D printing.

Filtering of Coffee Grounds

The project uses the Cafe Bustelo Instant Espresso Coffee grounds as the grains for granular jamming. As the coffee grounds are squished, they break down to even finer grains. These fine grains bypass the fabric filter and get sucked into tubing and vacuums. So, for the next iteration, I should use different grains that are bigger than the diameter of the spout (2.4mm) and find a mesh that can still catch these granules. The use of bigger granules may also help in achieving the finger nail feeling that I was trying to create because of how much space the silicone would have to conform too.

Related Works

Ramzi Abou Shahine, Steven Vasquez, Pooyan Fazli, Hasti Seifi. Clustering Social Touch Gestures for Human-Robot Interaction. In Proceedings of 15th International Conference on Social Robotics (ICSR), December 2023. 53-67. doi:10.1007/978-981-99-8715-3_6

Shahine et al, derived 9 main clusters of touch gestures based around the social, emotional, and contact characteristics of the 36 gestures to better understand the perceived similarities between each. Their findings form the foundation for the modular finger design. Scratching (Cluster 5: Aggression) and rubbing (Cluster 2: Caregiving Affection) were selected to explore how changes in stiffness can express different social intentions. Scratching includes the hardness of one's fingertip and the stiffness of the finger (low compliance), while rubbing uses the fingertip and the person’s relaxed muscles.

Saurabh Jadhav, Mohamad Ramzi Abdul Majit, Benjamin Shih, Jürgen P. Shulze, Michael T. Tolley. Variable Stiffness Devices Using Fiber Jamming for Application in Soft Robotics and Wearable Haptics. Soft Robotics, 9(1): 173–186, February 2022. doi:10.1098/soro.2019.0203

Jadhav, et al utilize fiber jamming to create a bendable, morphable tool, where the end effector behaves like a cantilever beam with adjustable compliance as air is vacuumed out. This method can also be used in a force feedback haptic glove for virtual reality, where the user experiences variable resistance in finger motion when interaction with different virtual objects. The fiber jamming used in this study acts as the stiffness adjuster for the fiber. As air is vacuumed out of the finger, the compliance is lowered and the user experiences a greater resistance to movement when pushing against the finger.

Eric Brown, Nicholas Rodenberg, John Amend, Annan Mozeika, Erik Steltz, Mitchell R. Zakin, Hod Lipson, Heinrich M. Jaeger. Universal robotic gripper based on the jamming of granular materials. Proceedings of the National Academy of Sciences, October 2010. doi:10.1073/pnas.1003250107

Brown et al. developed a soft robotic gripper enabled by granular jamming, allowing it to conform to the shape of a wide variety of objects. In its soft state, the gripper molds around an object, and as air is vacuumed out, it hardens and securely grips it. In this project, granular jamming is used within the finger to modulate hardness during touch interactions.